The aim of the MEPDG is to identify the physical causes of stresses in pavement structures (mechanistic) and calibrate them with observed pavement performance (empirical).

In CRCP, full-depth punchout, which is determined by the maximum tensile stress at the top of the concrete slab, is the only structural distress and besides the ride in terms of the international roughness index (IRI) are important performance indicators based on the American Association of State Highway and Transportation Officials (AASHTO) Interim Mechanistic Empirical Pavement Design Guide (MEPDG). For a well-performing CRCP, the Guide for Design of Pavement Structures (AASHTO 86/93) suggests that the CS should be between 1.07 and 2.44 m (3.5 and 8 ft). The CS is a critical factor in the performance of the CRCP. The CW is an important performance factor of CRCP because it controls the aggregate interlock and subsequent shear load transfer capabilities between concrete segments and is affected by concrete placement temperature and season, coarse aggregate type, drying shrinkage, bond-slip relationship between concrete and steel, steel reinforcement, subbase friction, and thermal movement.

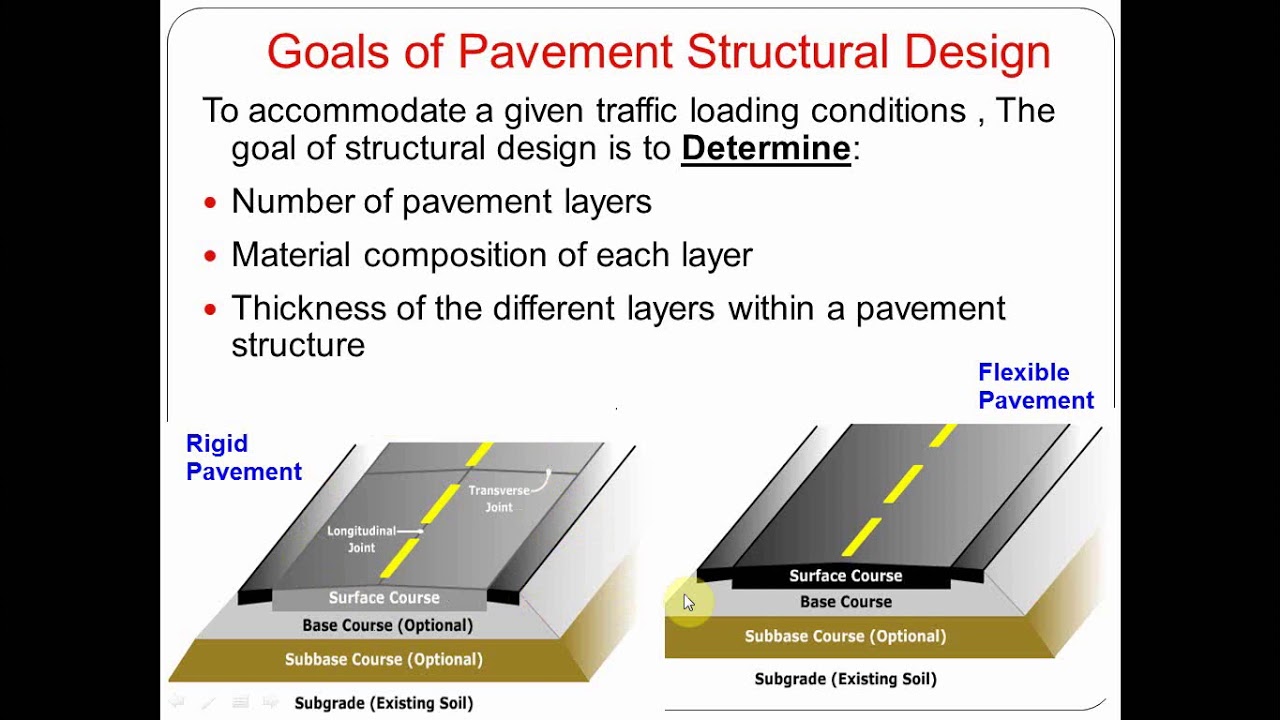

Figure 1 provides the structure of CRCP and the main influencing factors on the behavior of CRCP.Īn increase in the amount of longitudinal reinforcement will cause a decrease in the CW in CRCP because of immoderate cracking and loss of integrity of the pavement to act as a continuous slab the aggregate interlock increases the load transfer, SS decreases, the number of cracks increases, and stiffness at the transverse cracks improves.

#Concrete pavement design aashto crack#

The performance of CRCP is mainly related to material, construction factors, and crack patterns such as crack spacing (CS), crack width (CW), and steel stress (SS). As CRCP is constructed without any transverse joints, no repair and maintenance of joints are required which causes a significantly lower life cycle cost compared with jointed plain concrete pavement (JPCP). CRCP is preferred on high-priority routes due to its stability, durability, low maintenance requirements, high availability, and reduction of user delays caused by frequent maintenance and rehabilitation. CRCP is constructed with longitudinal reinforcement distributed along the pavement to hold the developing transverse cracks tightly closed, increase load transfer efficiency (LTE) across cracks, and provide stiffness by restraining end movement caused by concrete volumetric changes in the pavement slab under environmental loads. It is used mainly in highways and airports to accommodate heavily loaded traffic because of high yield and tensile strengths characteristics. The results show that the interactions between geometrics, material properties, traffic, and environmental conditions in the MEPDG method are more pronounced than in the AASHTO 86/93 and the prediction of CS and CW based on MEPDG matched closely with the recorded data from sections.Ĭontinuously reinforced concrete pavement (CRCP) is a unique rigid pavement with continuous steel bars throughout its length and no contraction transverse joints. In order to evaluate the CRCP design procedure and performance, crack width (CW) and crack spacing (CS) from five examined test tracks in Europe with different climate condition, base layer, geometry, and materials were collected in this paper and compared with predicted distresses as well as CW and CS from AASHTO 86/93 and MEPDG design methods. It functions by incorporating additional attributes such as environment, material properties, and vehicle axle load to predict pavement performance and degradation at the selected reliability level over the intended performance period. The MEPDG is a pavement design method based on engineering mechanics and numerical models for analysis. The AASHTO 86/93 is based on empirical equations to assess the performance of highway pavements under moving loads with known magnitude and frequency derived from experiments on AASHTO road tests. The Guide for Design of Pavement Structures (AASHTO 86/93) and Mechanistic Empirical Pavement Design Guide (MEPDG) are two common methods to design continuously reinforced concrete pavement (CRCP) published by the American Association of State Highway and Transportation Officials (AASHTO) in the USA.

0 kommentar(er)

0 kommentar(er)